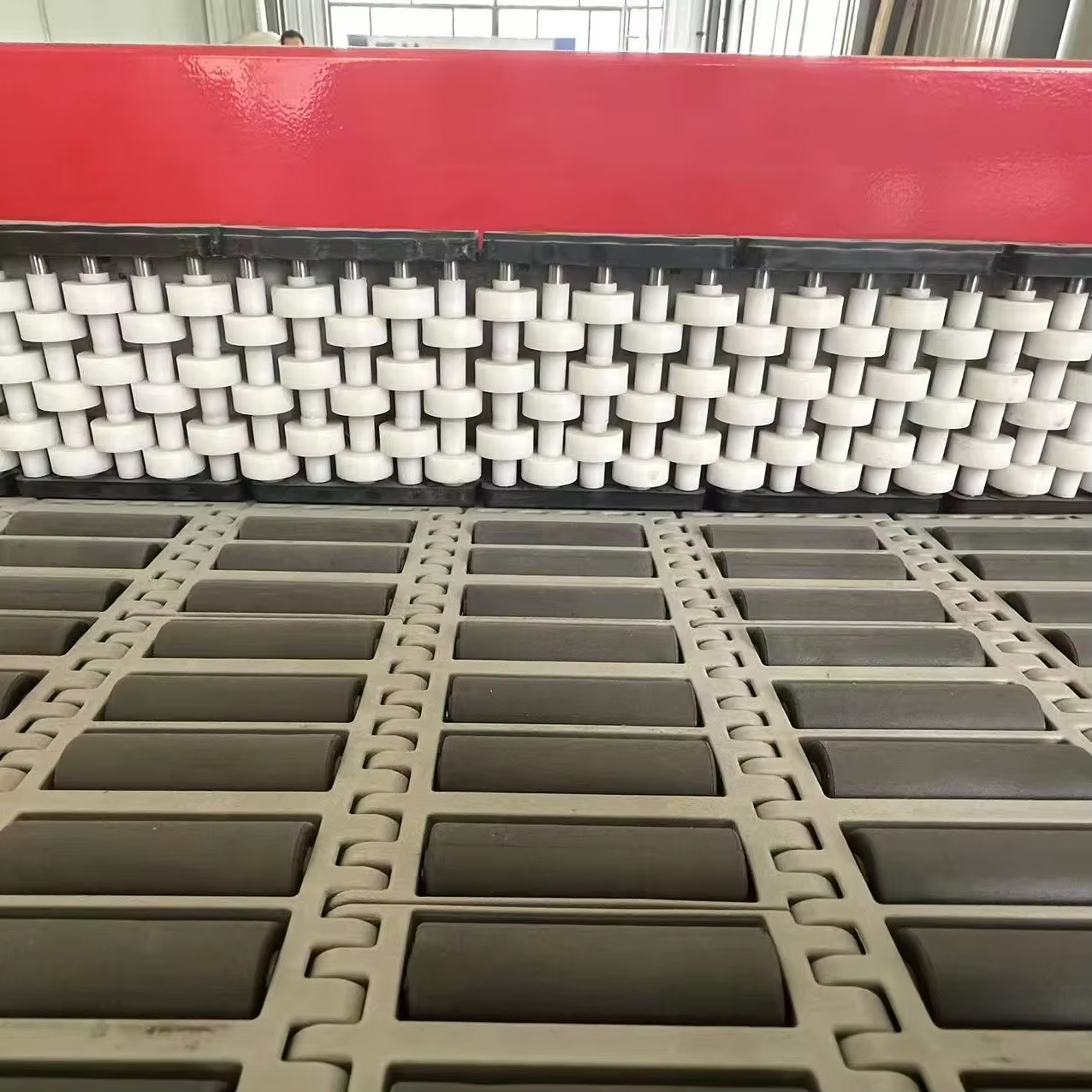

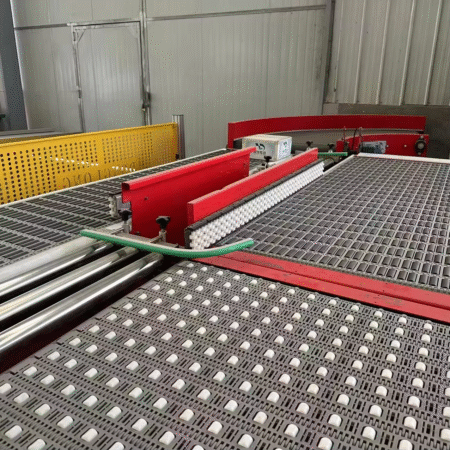

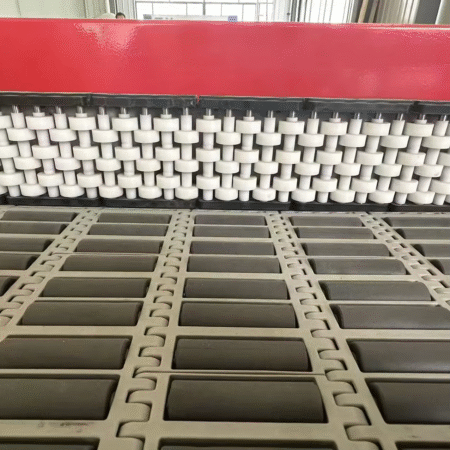

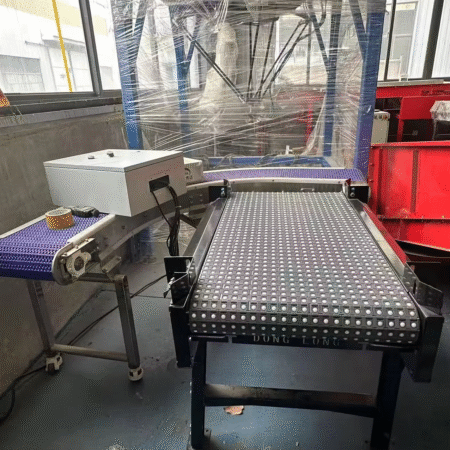

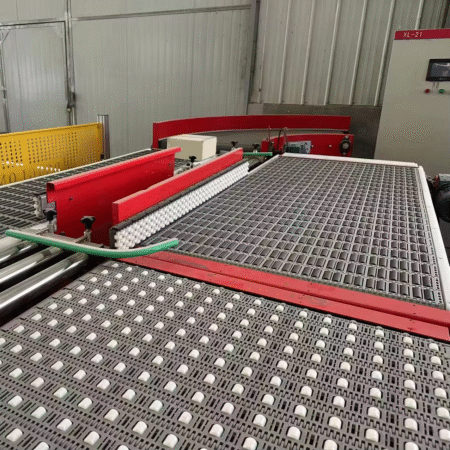

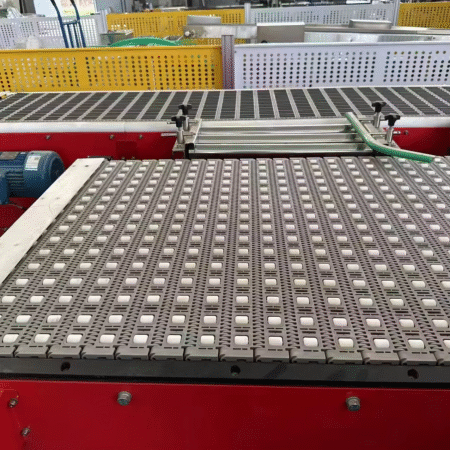

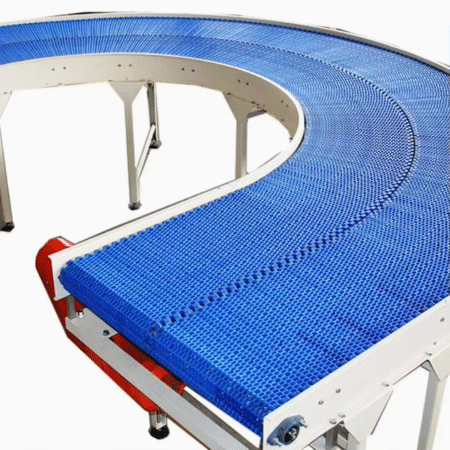

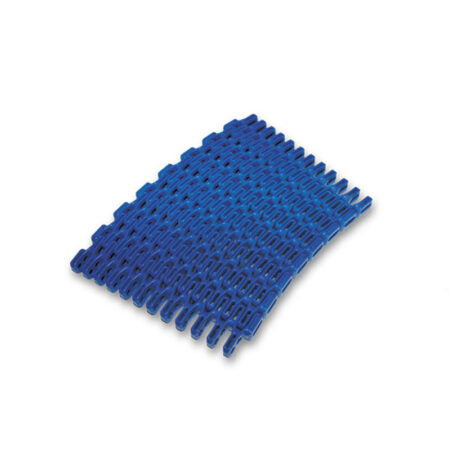

Modular belts (also known as modular conveyor belts) are assembled from standardized modules. They allow flexible customization of length and width, and can achieve complex conveying paths such as turning and climbing. Made of materials like food-grade engineering plastics, they are wear-resistant and corrosion-resistant. Their surface can be designed with structures such as anti-slip patterns and baffles, making them suitable for conveying various materials. With convenient maintenance (single modules can be replaced), they are widely used in industries including food, pharmaceuticals, logistics, and electronics, and serve as efficient and adaptable carriers for automated conveying.

| Product name | Auto High Speed Sorting System |

| Applicable industries | Logistics /Food/beverageManufacturing Agriculture/express sorting |

| State | New |

| Power | 1.5KW |

| Material | Stainless steel, carbon steel, customized |

| Colo | Offer customized services |

| Voltage | 220V |

| Belt material | PVC |

| Roller material | Carbon steel |

| Convryor speed | 0.1~5m/s |

| Open area ratio | 0% |

| Weight | 0.5/㎡ |

| Paymen | T/T |

| Warranty periodr | 1 year |

Superior Material, Long – lasting Durability:

Sturdy and Durable, High Load – bearing Capacity:

can be easily customized according to different conveyor systems and production line layouts. Whether it’s changing the length or

adapting to complex installation and adjustment requirements, it can handle them with ease.

Always a pre – production sample before mass production; this sample is strictly tested according to international and industry standards to ensure that all details meet the requirements. Always final Inspection before shipment; our quality control team conducts a comprehensive inspection of each batch of products, checking for any defects in appearance, size, and functionality.