Product Introduction: Precision Machined Sprockets for Roller Conveyors

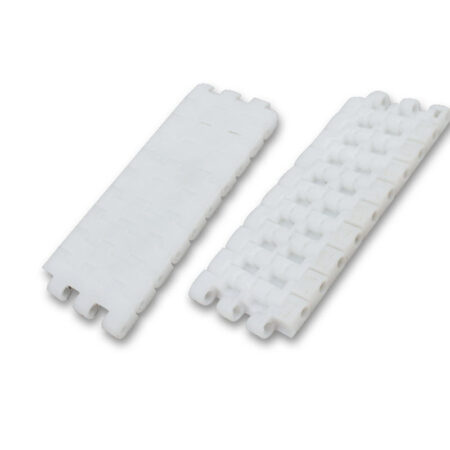

Product Name

Heavy-Duty Machined Sprockets

Category

Roller Conveyor Drive Components

Product Overview

Engineered for ultra-reliable power transmission in roller conveyor systems, our CNC-machined sprockets deliver unmatched precision and longevity. Manufactured to ISO 606 standards, they ensure perfect chain engagement and minimize wear for critical drive applications in logistics, manufacturing, and heavy-material handling.

Key Features

Aerospace-Grade Machining: CNC-hobbed teeth with surface hardening (HRC 45-55) for <0.05mm runout tolerance

Universal Compatibility: ANSI/BS/DIN standard sizes (25-100 teeth) with taper lock or keyed bore options

Zero-Failure Design: Triple-sealed bearings and phosphate-coated surfaces prevent corrosion and contamination

Energy Efficient: Helical tooth profiles reduce chain friction by 25% vs. standard sprockets

Technical Specifications

| Parameter | Specification |

| Materials | 4140 Alloy Steel, SS316, Nylon-Coated |

| Bore Sizes | 20–150 mm |

| Temperature Range | -40°C to +180°C |

| Standards | ISO 606, ANSI B29.1 |

Product Introduction: Magnetic Turning Chain for Curve Rollers

Product Name

Magnetic Turning Chain System

Category

Roller Conveyor Guidance Systems

Product Overview

Revolutionize curved conveyor sections with our magnetic turning chain technology. This innovative system uses embedded neodymium magnets to guide rollers without physical contact, eliminating friction and maintenance in high-speed sorting centers, airport baggage systems, and automotive assembly lines.

Key Features

Frictionless Navigation: Magnetic field alignment reduces roller drag by 90% compared to mechanical guides

Self-Correcting Design: Auto-adjusts roller angles during direction changes (30°–180° curves)

Maintenance-Free Operation: No lubrication required with IP69K-rated sealed housing

Smart Integration: Compatible with PLC control for dynamic speed adjustment

Technical Specifications

| Parameter | Specification |

| Magnet Strength | N52 Grade NdFeB (12,500 Gauss) |

| Curve Radius | 600–3000 mm |

| Load Capacity | ≤150 kg/roller |

| Operating Speed | 0.5–5 m/s |

Why Choose Chenming for Roller Conveyor Systems?

✅ Precision Manufacturing: ±0.01mm tolerance guarantees component interoperability

✅ Proven Durability: 50,000+ hour MTBF certification on all drive components

✅ Custom Solutions: Tailored sprocket/chain configurations for unique layouts

Upgrade Your Conveyor Performance

📞 Tel: +8615588899013

✉️ Email: liang@chenming-conveyor.com

“Where Engineering Meets Motion”

Shandong Chenming Intelligent Equipment Co., Ltd.