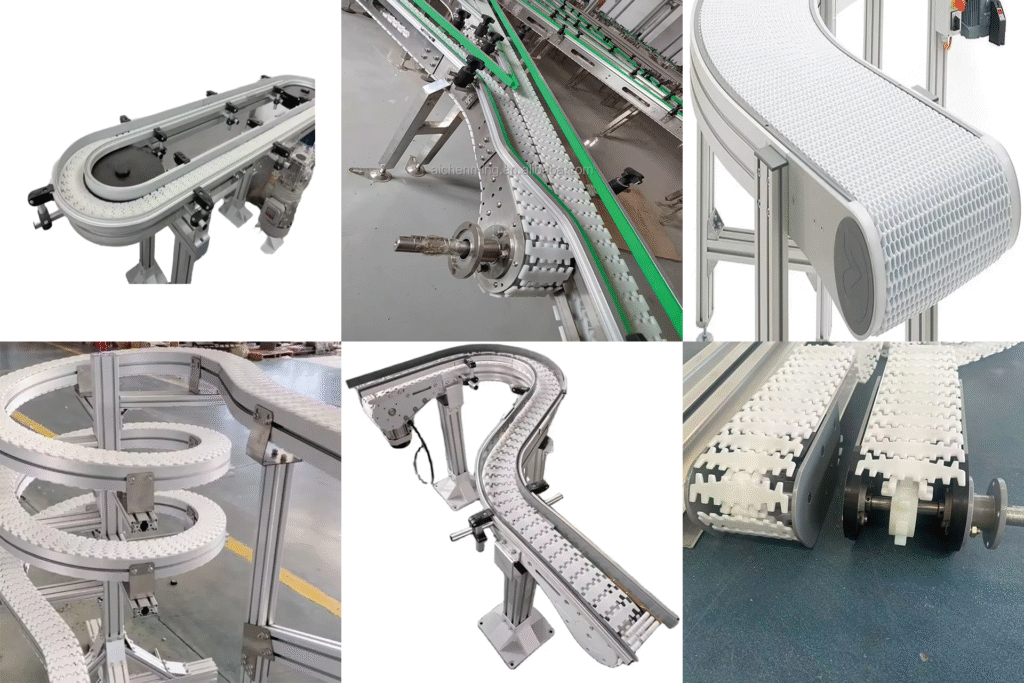

As a highly adaptable new type of chain plate conveyor system, the flexible chain conveyor can be flexibly combined and installed according to the actual scene of the customer’s site, perfectly meeting the diverse working environment requirements. The whole machine adopts an aluminum alloy frame, and the conveying carrier is a flexible chain plate made of plastic steel material. The raw material particles of the chain plate are mostly injection molded from high-quality materials such as Baoli from Japan or DuPont from the United States, which have both durability and adaptability, and are widely used in multi industry assembly lines.

1、 Core classification of flexible chain conveyor

According to the differences in conveying scenarios and functions, flexible chain conveyors are mainly divided into three categories, accurately covering different conveying needs:

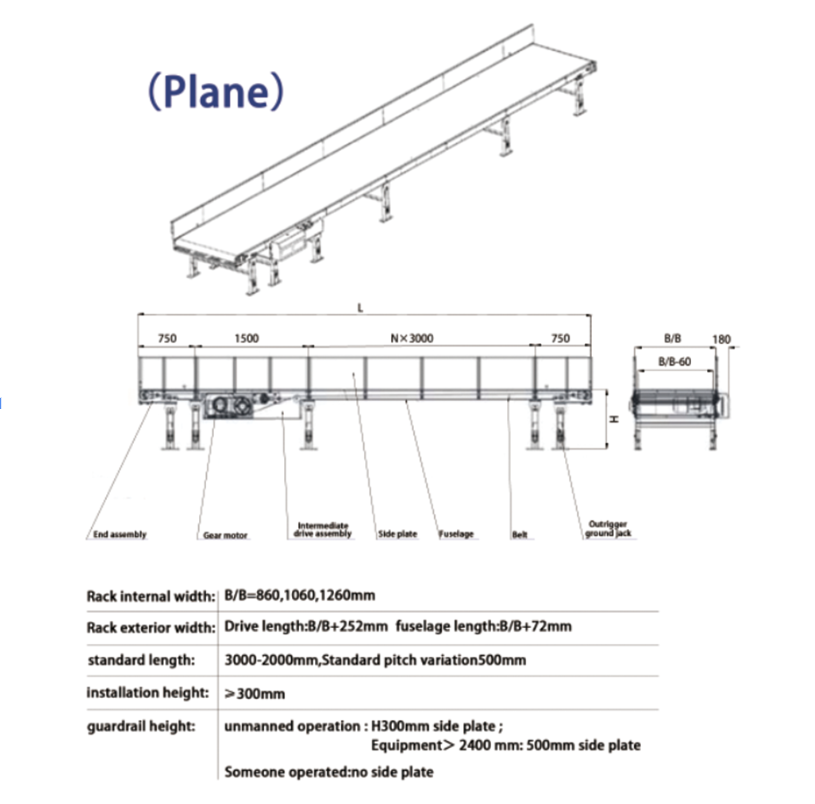

a. Flat flexible chain conveyor: focusing on material transportation within a single plane, it can achieve flat trajectory operation such as straight lines and turns, and is suitable for horizontal material transportation, sorting and other scenarios.

b. Clamp type flexible chain elevator: focusing on vertical conveying in three-dimensional space, it can stably achieve vertical lifting or lowering of materials, effectively solving the problem of material connection between multi-layer workshops and high and low workstations.

c. Climbing downhill flexible chain conveyor: designed for inclined conveying needs in flat space, the slope can be adjusted according to the production process requirements, and it is suitable for transitional conveying of materials on production lines of different heights.

2、 Core advantages of flexible chain conveyor

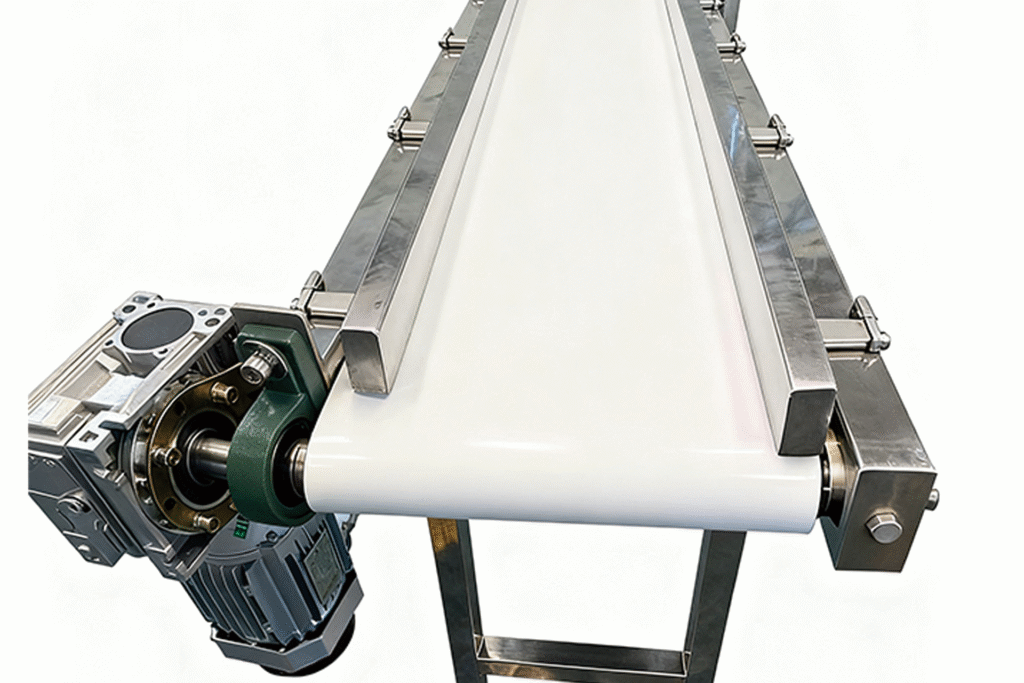

a. Excellent compatibility between appearance and environment: The integrated design of the whole machine has a strong sense of integration, with a beautiful and clean appearance, low noise during operation, and no pollution generated, which can be integrated into production scenarios with strict environmental requirements.

b. Easy and efficient installation: The modular structure design significantly reduces installation difficulty, allowing for quick assembly and minimizing interference with the production site.

c. Health and safety standards: The aluminum alloy frame is corrosion-resistant, and the plastic steel chain plate has no odor and is easy to clean, fully meeting the industry standards for high health and safety requirements in food, medicine, and other fields. It is commonly used in beverage factories, milk/powder production workshops, pharmaceutical factories, food processing plants, and other scenarios.

3、 Standardized installation and operation process of flexible chain conveyor

a. Clearly define the core modular components

Before installation, it is necessary to confirm that the core modules of the equipment are complete, mainly including: drive head and tail, body section conveyor beam, connecting plate, support profile, aluminum casting foot, guardrail components, motor and electrical control box.

b. Complete the installation operation step by step

① The construction of the basic support structure first involves fixing the aluminum casting feet and supporting profiles with bolts, accurately determining the foot position to ensure the stability of the equipment; Subsequently, the conveying beam of the fuselage section is docked with the assembled support frame, and the equipment foundation frame is constructed by fastening it with connecting plates.

② The assembly of the driving head and tail with the main structure is carried out according to the preset material conveying direction. The driving head and tail are installed at both ends of the conveying beam to ensure alignment with the center-line of the conveying beam. After tightening the bolts, the main structure of the equipment is basically formed.

③ Installation and disassembly of the flexible chain plate on either side of the drive head and tail, aligning the flexible chain plate with the chain plate guide rail of the conveyor beam and slowly inserting it. After the two ends of the chain plate are docked, assemble it into a circular closed loop, and use specialized connectors to fix the chain plate joints; Adjust the tensioning device at the head and tail of the drive to ensure that the tension of the chain plate is moderate (press the middle of the chain plate by hand to control the sinking within a reasonable range), and finally reinstall the disassembled panel and tighten it.

④ The installation of guardrails and power systems is based on the actual size of the conveyed materials, adjusting the height and spacing of the guardrails, and fixing the guardrail components on both sides of the conveying section; Install the motor at the designated installation position on the drive head, and then connect the motor power and control wires to the electrical control box to ensure that the wiring complies with electrical specifications and the grounding is reliable.

4、After installation, empty car test machine inspection

After assembly, an empty test drive is required: connect the power supply, start the equipment, observe whether the chain plate runs smoothly, whether there is any jamming or deviation, confirm that the motor runs normally and has no abnormal noise, and after the test drive is successful, the equipment can be put into subsequent use.

As a key component of assembly lines in industries such as food, beverage, chemical, and automotive interiors, flexible chain conveyors can effectively improve production efficiency and transportation stability. Shandong Chenming Intelligent Equipment Co., Ltd., as a professional manufacturer of flexible chain conveyors, can provide customized solutions. We welcome customers from all walks of life to consult and cooperate.