In the field of industrial production, assembly lines have become the core configuration for improving production efficiency with standardized and continuous operation modes. Their characteristics and defects are closely related to the adaptability of production scenarios. The specific analysis is as follows:

1、 Core feature: Adapt to efficient production needs

a. Wide range of conveying functions: It can stably transport bulk materials (such as chemical raw materials and grains), as well as heavy packaged objects (such as mechanical components and finished products), adapting to the material conveying needs of different industries and reducing manual handling costs.

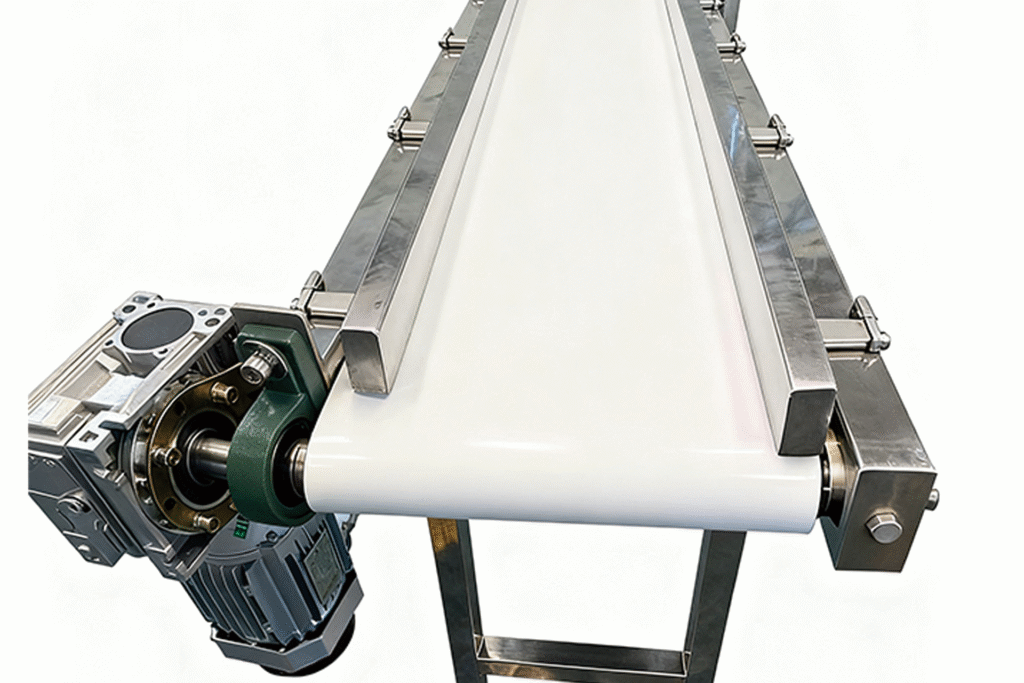

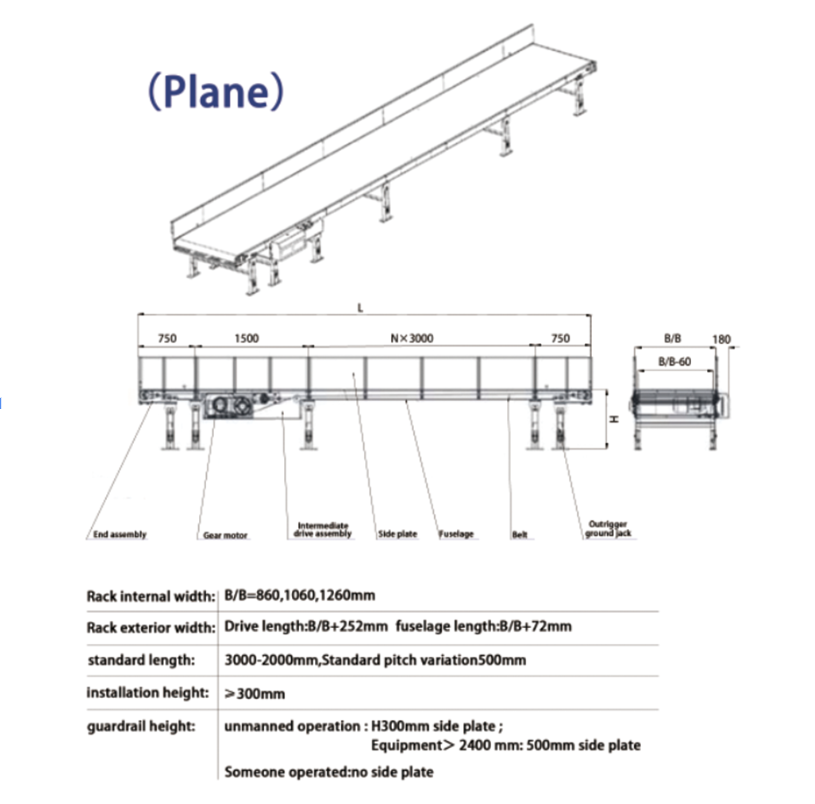

b. Flexible equipment combination: Various equipment such as belt conveyors, screw conveyors, and lifting conveyors can be combined and used according to the differences in enterprise processes. For example, in the food industry, the “elevator+belt conveyor” is used to achieve the connection between vertical and horizontal material transportation, meeting complex production processes.

c. Stable and efficient operation: It achieves uninterrupted and continuous cyclic operation according to the preset route, with controllable conveying rhythm, smooth operation, low noise, and the advantage of “long-distance conveying (up to tens of meters)+high carrying capacity (single line hourly conveying capacity can reach tons)”, suitable for large-scale production.

d. Strong environmental adaptability: able to customize enclosed and dust-free conveying spaces (such as in the pharmaceutical and electronics industries) based on the requirements of the workplace and hygiene, to avoid material contamination from the outside world; The route direction can also be adjusted according to the workshop layout (such as straight lines, turns, and climbing), maximizing the use of production space and ensuring product quality and production orderliness.

e. Assist in automation management: By combining with sensors and PLC control systems, automated operations such as material positioning, counting, and sorting can be achieved, reducing manual intervention errors and facilitating unified monitoring and management of production processes for enterprises, promoting the upgrading of production automation.

2、 Potential defects: limited by the scene and mode

a. Lack of flexibility and high cost of transformation: The lines and equipment combinations of the assembly line are mostly fixed designs. If the production product specifications are adjusted (such as material size and weight changes) or the process is upgraded, the equipment structure and conveying parameters need to be significantly modified. This not only takes a long time, but also incurs high equipment replacement and debugging costs, making it difficult to quickly adapt to the production needs of multiple varieties and small batches.

b. Relying on overall collaboration, a single point of failure affects the overall situation: The assembly line operates in a continuous mode, with closely connected equipment and processes. If a certain link (such as drum jamming or belt breakage) fails, it will cause the entire production line to come to a halt, requiring shutdown for troubleshooting and maintenance, which will have a direct impact on production progress, especially in industries that are sensitive to production pace (such as fast-moving consumer goods) where losses are significant.

c. High upfront investment and maintenance costs: Building a standardized assembly line requires the purchase of multiple specialized equipment and supporting control systems, resulting in a high upfront capital investment; In daily maintenance, it is necessary to regularly inspect and replace vulnerable components such as motors, bearings, and conveyor belts, and the maintenance cost of some core components (such as imported frequency converters and special conveyor belts) is high, which increases the long-term operational burden of the enterprise.

d. Strict requirements for site and layout: Although it can adapt to site adjustments, there are certain requirements for workshop floor flatness and spatial height (such as sufficient vertical space for lifting conveyors); If the workshop layout is compact or there are irregular obstacles, it may limit the line design of the assembly line, requiring additional site renovation and increasing the difficulty of early preparation.

e. The standardization of personnel skills and limited adaptability: Workers on the assembly line are mostly responsible for a single process (such as sorting and assembly), and their skills are relatively limited. If the enterprise adjusts the production category or process, it needs to retrain employees, otherwise it will be difficult to quickly adapt to the new position, indirectly affecting production efficiency; Meanwhile, prolonged repetitive work may also lead to employee fatigue and increase the risk of operational errors.