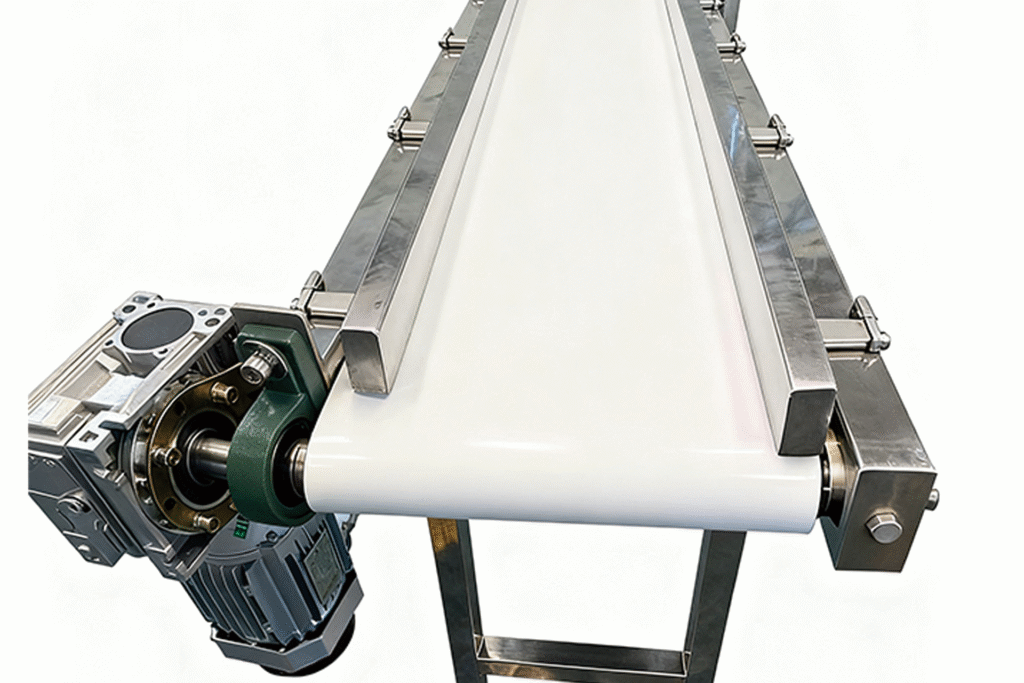

In the composition of automated conveyor lines, roller conveyor lines are indispensable basic equipment. With its simple structure and strong durability, it has become a standard device in logistics, warehousing, manufacturing and other fields. It achieves material transmission through the rotation of rollers, and can adapt to various forms of goods such as bagged, boxed, and bulk. It also has the advantages of stable operation and convenient maintenance, providing reliable support for automated material flow in various scenarios.

With the development of automation technology, roller conveyor lines are continuously being optimized and upgraded. In the future, they will further advance towards efficiency, intelligence, and environmental friendliness, better serving operational needs in areas such as express delivery sorting, e-commerce fulfillment, and industrial production.

1、 Core Advantages of Roller Conveyor Line

a. Strong adaptability : The roller conveyor line is compatible with various carriers and cargo forms, such as cartons, sacks, pallets, and plastic baskets. By adjusting the roller spacing, diameter, or material (such as metal rollers for heavy goods and plastic rollers for light goods), it can meet the conveying needs of goods with different weights and shapes. For special scenarios, baffles, guardrails, or turning and climbing structures (with a maximum climbing angle of about 15°) can be added to flexibly adapt to complex site layouts.

b. High conveying efficiency : The roller speed can be adjusted according to demand, and the increase in speed directly increases the conveying volume per unit time. By increasing the number of roller groups to achieve “multi-channel parallel conveying”, the overall efficiency can be further improved. With the combination of photoelectric sensors and variable frequency motors, “on-demand speed regulation” can be achieved – high-speed operation during peak orders and low-speed energy saving during low periods, accurately matching production and sorting rhythms.

c. Easy maintenance : The core structure of the equipment consists of a roller, a bracket, and a drive motor, with no complex precision components. Daily maintenance only requires regular inspection of the bearing lubrication status, tightening of loose screws, cleaning of equipment dust, and replenishment of lubricating oil. The operation is simple and time-consuming (about 10 minutes per maintenance). At the same time, it adopts a modular design, allowing for individual replacement of damaged rollers without requiring the entire machine to be shut down, minimizing the risk of production interruptions.

d. High reliability : The material is transported by rolling on a roller, with a small contact surface with the equipment, low friction and collision probability, which can reduce the loss of goods due to squeezing and scratching, and reduce the incidence of equipment failure. The core component roller is mostly made of wear-resistant materials such as stainless steel and high-strength plastic, with a service life of 5-8 years, ensuring long-term stability during the conveying process.

2、 Main Application Fields

a. Logistics and Warehousing Sector : In the express sorting center and warehousing and shipping processes, roller conveyor lines are responsible for the transfer and loading/unloading of parcels and full-container loads, supporting high-throughput sorting and storage circulation needs.

b. Manufacturing field : Widely used in automobile, electronics, food and other factories, responsible for the transmission of parts and semi-finished products between various processes, connecting production processes and ensuring continuous operation of production lines.

c. E-commerce field : During the e-commerce promotion period, the roller conveyor line supports the entire process of material circulation in the warehouse, including “packaging-sorting-outbound”, to efficiently handle the high demand for processing massive orders and avoid cargo accumulation.

d. Food and beverage, pharmaceuticals : In the food processing workshop, the material conveying and the pharmaceutical warehouse, the pharmaceutical transfer, the food grade, anti-corrosion material roller conveyor line can be used to meet the hygiene and safety standards.

3、 Precautions for Use

a. Prevent cargo from being stuck : Regularly check the roller spacing and side plate status, clean the dust, packaging tape and other debris inside the equipment; install a photoelectric detection device to automatically alarm and stop the machine when it detects that the goods are stuck, avoiding damage to the goods and equipment.

b. Ensure the goods are placed stably : When placing goods, ensure that the center of gravity is stable to prevent slipping or rolling; for round, easily rolling goods, add baffles or partitions to secure them.

c. Replace the worn roller in time : Regularly check the smoothness of the roller’s rotation and the wear condition of its surface. If the roller is severely worn or the bearing is aging, replace it in time to ensure the conveying efficiency.

As the basic equipment for automated conveying, roller conveyor lines have become an important support for efficient operation in logistics, manufacturing, and other industries due to their adaptability, efficiency, and reliability. Their simple and practical design characteristics have made them a core component in various automation scenarios.