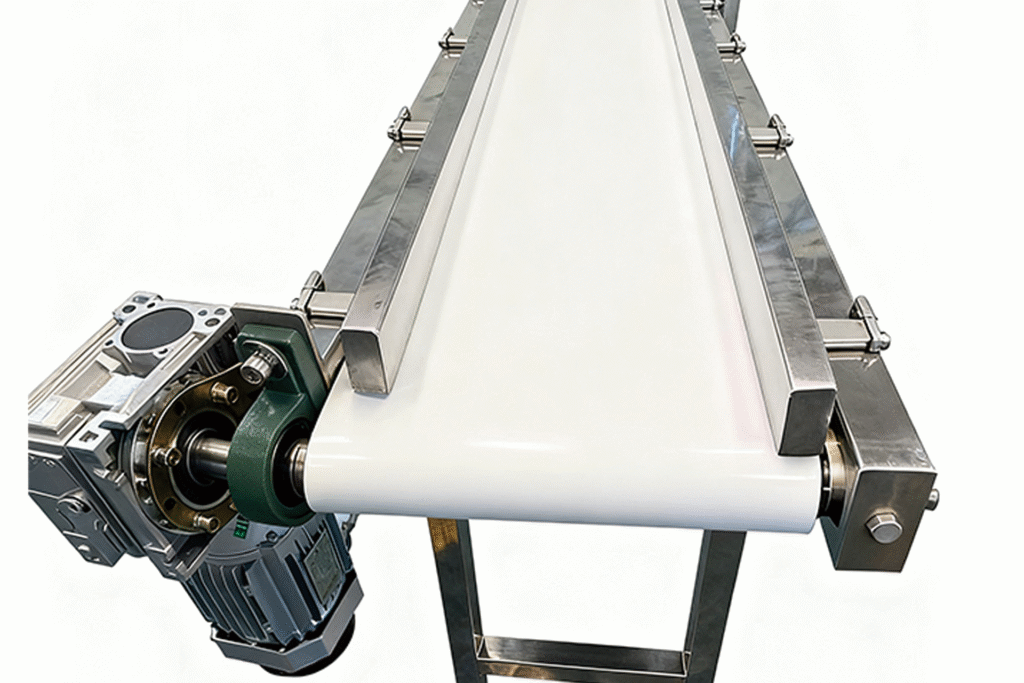

Knife edge turning belt conveyor is a special belt conveyor system designed for material turning and conveying needs. Its core highlight lies in the “knife edge” structure at the turning point – through precise design of small shaft diameter and small docking area, it achieves smooth transition of materials during the turning process, while reducing conveying resistance and providing efficient solutions for multi scenario material transportation.

1、 Core design: Technical advantages of the “knife edge” structure

The “knife edge” design is the core technical highlight of this equipment, which is different from the large arc transition of traditional turning belt lines. It achieves performance improvement through two aspects of optimization:

a. Small shaft diameter design: The transmission shaft diameter at the turning point is smaller, reducing contact friction with belts and materials, reducing energy loss during the conveying process, and improving system operating efficiency;

b. Small docking area: The contact area at the turning joint is streamlined to avoid material deviation or loss caused by “stuck points” during turning, ensuring stable and controllable transmission trajectory.

2、 Core advantage of the equipment: adaptability to multiple scene transportation needs

a. The transition of materials is smoother relying on the “knife edge” structure. When turning, materials can smoothly turn along the preset trajectory, effectively reducing material scattering, collision or damage caused by centrifugal force and frictional resistance. It is especially suitable for conveying fragile and easily offset materials (such as packaged products and precision parts).

b. The design of small shaft diameter and small docking area highlights the conveying efficiency, significantly reducing the system’s operating resistance and energy loss. At the same time, it can adapt to higher conveying speeds. Compared with traditional curved belt lines, the overall conveying efficiency is significantly improved.

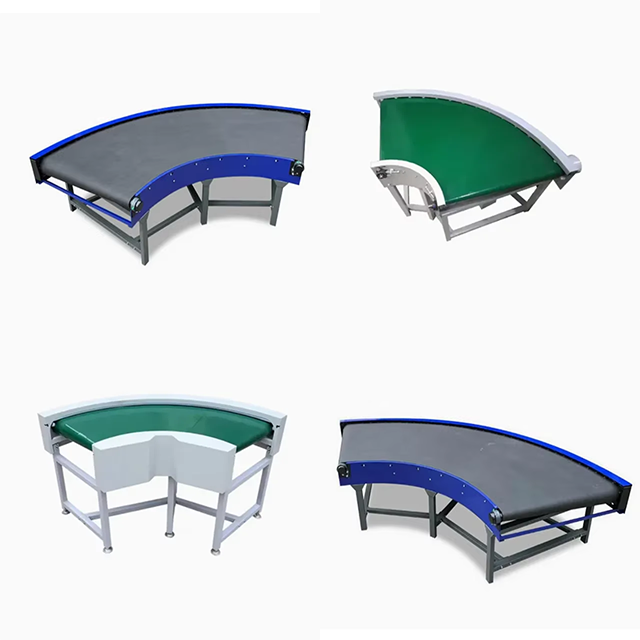

c. The adaptability of the scene is wider and not limited by the shape or size of the material. Whether it is small parts, block materials, or packaged products, they can be stably transported; Especially in scenarios that require continuous turning in multiple directions (such as “L-shaped”, “U-shaped”, “Z-shaped” conveyor paths), there is no need to add additional steering equipment, simplifying the conveyor process.

3、 Practical application: covering core transportation scenarios across multiple industries

The knife edge turning belt line, with its efficient and smooth characteristics, is widely used in fields such as warehousing and logistics, production and manufacturing. Typical application scenarios include:

a. Warehouse logistics: Multi directional sorting and transportation of e-commerce warehouse sorting lines and express transit, achieving continuous transfer of materials from storage, sorting to outbound;

b. Production and manufacturing: Production lines in industries such as food processing, electronic components, and automotive parts, connecting material transfer between different processes (such as turning and conveying from assembly stations to testing stations) to ensure continuous operation of the assembly line;

c. Packaging industry: Multi directional transportation of packaged products, turning and sorting before palletizing to avoid manual intervention and improve automation production level.

In summary, the blade turning conveyor belt is centered around “precision structure+high efficiency performance”, solving the pain points of traditional turning conveyor equipment such as poor stability, low efficiency, and limited scenarios. It has become an indispensable key conveyor equipment in modern logistics sorting and industrial production lines, providing reliable support for multi-directional and high-efficiency material transportation.