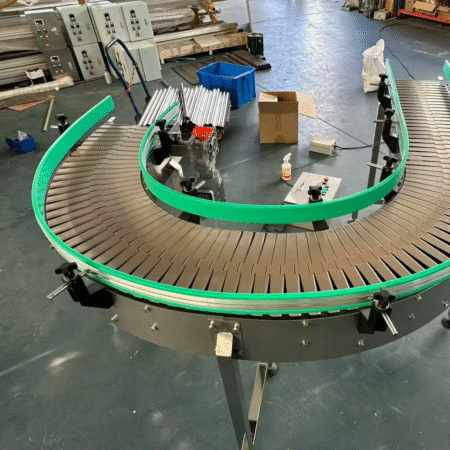

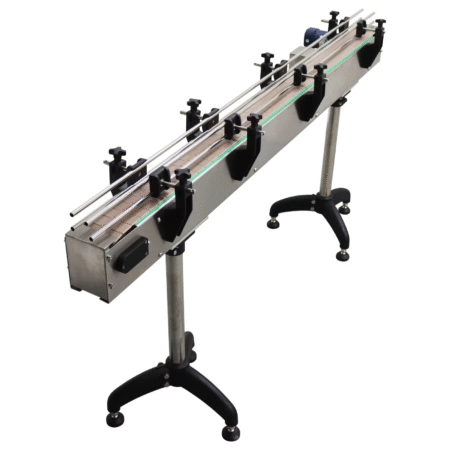

Product Introduction: Precision Toothed Chain Conveyor System

System Components

Toothed Chain Sprocket

Wide Toothed Flat Chain

Toothed Flat Chain

Wide Toothed Chain Sprocket

Category

Heavy-Duty Chain Conveyor Drive Systems

Engineering Breakthrough

Our ISO 1977-certified toothed chain system eliminates slippage in high-torque applications through patented Tri-Lock Engagement Technology™. The precision-machined teeth and chains maintain synchronous movement even under 15% overload conditions – ideal for automotive assembly, timber processing, and steel rolling mills.

Component Synergy

| Component | Innovation Highlights | Performance Advantage |

| Wide Toothed Flat Chain | • 40% wider tooth contact area • Forged manganese steel links • Self-lubricating bushings |

Handles 200 kN tension without elongation |

| Precision Toothed Sprockets | • CNC-hobbed teeth (AGMA 9 precision) • Dynamic balance tested (G6.3) • Laser-etched timing marks |

±0.02° angular transmission accuracy |

| Toothed Flat Chain | • Diamond-coated wear strips • RFID-embedded links • Oil-impregnated sintered alloy |

0.0001% slip rate at 500 RPM |

| Wide Toothed Sprocket | • Dual-helix tooth profile • Cryogenically treated cores • Quick-change segmented design |

80% longer service life than ASME B29.1 |

Technical Specifications

Chain Performance Data

markdown

– Pitch Range: 25.4–152.4 mm (1″–6″) – Tensile Strength: 180–2,200 kN – Temperature Tolerance: -55°C to +315°C – Noise Level: 52 dB(A) at 3 m/s

Sprocket Precision Metrics

markdown

– Tooth Count: 12–72 teeth – Bore Tolerance: H7/h6 (ISO 286) – Runout: <0.03 mm TIR – Surface Hardness: 58–62 HRC

Industry-Leading Advantages

Zero Energy Waste

99.8% power transmission efficiency (verified by TÜV Rheinland)

Predictive Maintenance

Wireless strain sensors detect chain fatigue 500+ hours before failure

Retrofit Ready

Compatible with DIN 8153/ISO 1977 systems

Extreme Environment Proof

IP69K sealing withstands high-pressure washdowns

Application Showcases

Automotive Powertrain

“Deployed in BMW’s EV battery line: Sustained 0.5mm positioning accuracy across 2km conveyor at 18m/min”

Lumber Processing

“Operates in Canadian sawmills: 7,000+ hours between maintenance cycles despite sawdust contamination”

Steel Coil Handling

“Handles 45-ton coils at POSCO’s cold rolling plant: 0% downtime since 2021 installation”

Why Engineers Specify Our System

✅ Matched Component Warranty

5-year unified warranty covering chains AND sprockets

✅ Digital Twin Integration

Download 3D models (STEP/IGES) for system simulation

✅ Global Critical Response

24/7 technical support with 4-hour emergency protocol

Request Performance Validation

📞 Tel: +8615588899013

✉️ Email: liang@chenming-conveyor.com

Precision Engineered for Relentless Production

Shandong Chenming Intelligent Equipment Co., Ltd.

Where Every Tooth Matters™