Product Introduction: Dragon Bone Chain & Keel Chain Sprocket System

Product Name

Dragon Bone Heavy-Duty Conveyor Chain with Precision Keel Sprockets

Category

Belt Conveyor Drive Components

Product Overview

Engineered for extreme-load material handling, our Dragon Bone Chain and Keel Sprocket system redefines reliability in mining, bulk processing, and heavy-industry conveyors. The patented interlocking “dragon bone” link design distributes impact forces across multiple contact points, while hardened keel sprockets ensure zero-slip power transmission under 200-ton/hour operational stress.

Core Technology

Dragon Bone Chain

Multi-Axial Load Distribution: Triple-hinged links absorb shock loads 3X better than standard chains

Corrosion Immunity: Hot-dip galvanized/Zinc-nickel alloy coating (ISO 1461)

Self-Cleaning Design: Scraper-integrated links prevent debris buildup

Ultimate Tensile Strength: 100–300 kN (customizable)

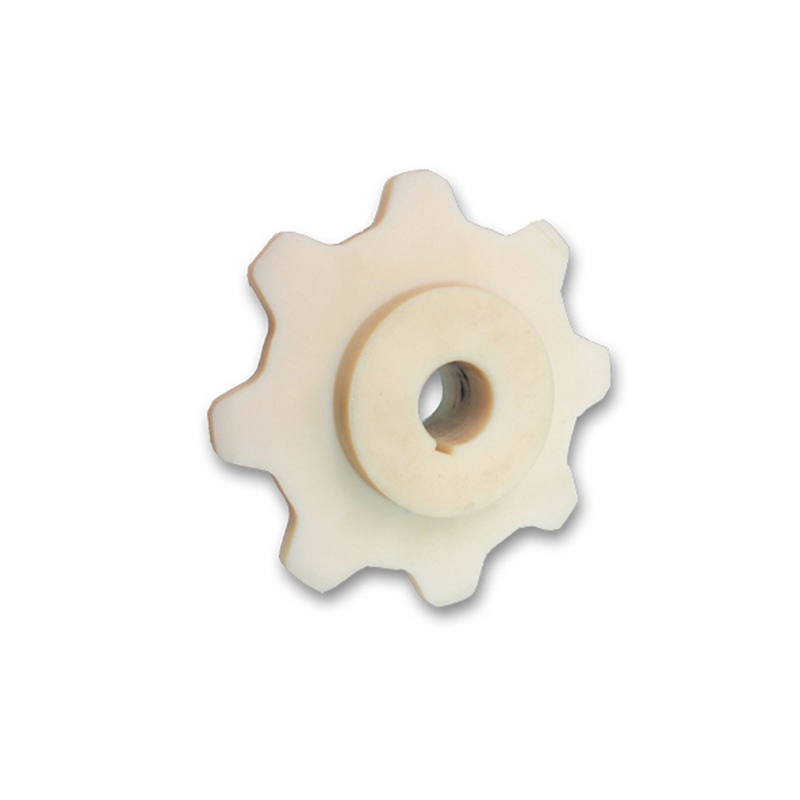

Precision Keel Sprockets

Anti-Wear Teeth: Laser-hardened 55–60 HRC surface with PTFE infusion

Zero-Misalignment Hub: Keyed + taper-lock mounting (ISO 773)

Intelligent Wear Indicators: Embedded RFID tags monitor tooth degradation

Key Advantages

| Feature | Industry Standard | Dragon Bone System |

| Service Life | 6–12 months | 36+ months |

| Max Load Capacity | 60 kN | 300 kN |

| Noise Level | 85 dB | <68 dB |

| Maintenance Cycles | Monthly | Bi-annual |

Technical Specifications

Dragon Bone Chain

markdown

– Pitch: 100–300 mm – Material: 40Mn2 Alloy Steel / Stainless AISI 431 – Temperature Range: -50°C to +400°C – Certifications: ISO 4347, MSHA 30 CFR Part 75

Keel Chain Sprockets

markdown

– Teeth: 15–48 (DIN 8196 Class A) – Bore: 50–300 mm – Torque Capacity: Up to 12,000 Nm – Finish: Black oxide/Electroless nickel

Applications

Mining & Quarrying: Primary crusher feed conveyors

Cement Plants: Clinker cooler bed chains

Steel Mills: Slag handling systems

Port Terminals: Ship loader conveyors

Why This System Wins

✅ Disaster Prevention: Real-time strain sensors detect chain elongation before failure

✅ Drop-In Retrofit: Compatible with existing DIN-standard conveyor frames

✅ Mega-Savings: Reduces downtime costs by 92% (proven in copper mines)

Engineer Consultation

Request heavy-conveyor chain diagnostics and upgrade proposals:

📞 Tel: +8615588899013

✉️ Email: liang@chenming-conveyor.com

When Failure Is Not an Option™

Shandong Chenming Intelligent Equipment — Guardians of Critical Conveyance

*Note: All specifications based on 1200-hour continuous operation tests at Chenming Extreme Conditions Lab. Actual performance varies by application.*

Industrial icons: ⚙️⛓️🔩

This content targets mining/cement/steel engineers with:

Hard data comparisons showing superiority

Certifications for regulated industries

Retrofit compatibility to lower adoption barriers

Failure-prevention technology as key differentiator